Have you ever wondered why a replacement toner cartridge costs $300 or, sometimes, even more? Have you ever thought, boy, I didn't pay much more than that for the printer in the first place! Have you been online and seen it's possible to buy a cartridge off the Amazon marketplace for as little as 10% of what you have to pay for an OEM cartridge from OfficeDepot or Staples? Have you had a bad quality experience buying online? Worse still, have you had a good experience but, then, when you go back to Amazon, the original seller is nowhere to be found and you have to place your trust in another anonymous seller? You simply have no idea if it's going to be a good experience or a bad experience.

Well, that's why we're going to help you!

First, we thought you may appreciate an explanation of the costs to build a typical laser cartridge and to understand some of the background of why they're priced the way they are.

Then, second, we're going to help you understand why there are high-quality alternatives and reputable resellers that can help you save money without sacrificing quality.

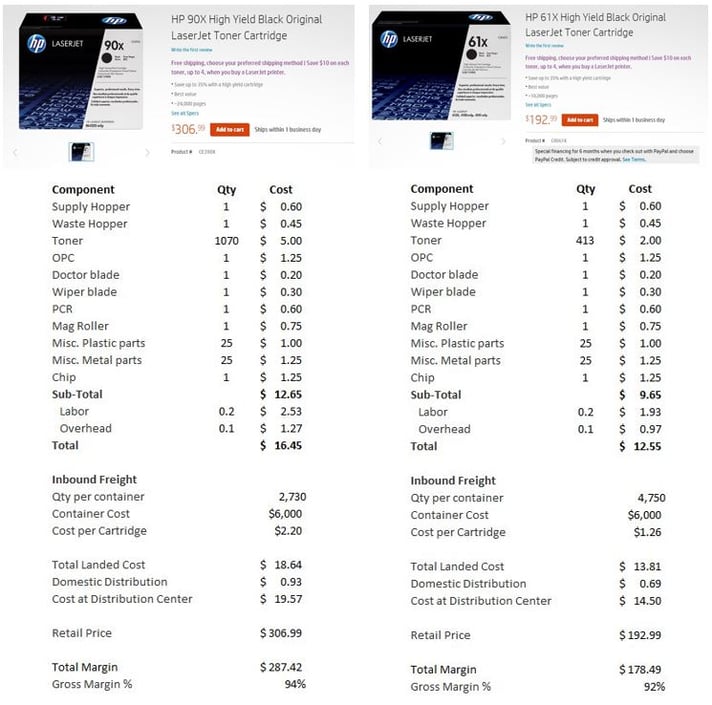

Below is a schematic of a typical laser cartridge and beneath it a costed bill of materials.

The material cost in a typical laser cartridge is around $15 to $20. Of

A cartridge used in a high volume business environment may have as much as thirty times the yield of a small personal printer cartridge but would be priced at only around four-times that of the lower yield cartridge. For the most

Broadly speaking, most cartridges manufactured by the OEMs have a delivered cost somewhere between $8 and $25 depending on the page yields.

There are two examples shown directly below showing the listed prices of OEM brand products as of March 2017 alongside the estimated manufacturing and distribution costs.

What's the takeaway?

Laser cartridges that cost between $15 and $20 to get from the offshore factory to local distribution centers across the United States for resale between $200 to $300

The underlying reason for the high prices on consumables was the desire of the original equipment manufacturers (OEMs) to build the largest possible installed base of printing devices that would go on to consume the high priced cartridges. In order to achieve this objective, the printing devices were priced at or below their true cost. By offering businesses and consumers low-cost printing devices then mass adoption was enabled. The cartridges subsidize the hardware so ultimately the consumers of the cartridges end up paying the true cost of the printer - it was just put off to some point in the future!

The underlying reason for the high prices on consumables was the desire of the original equipment manufacturers (OEMs) to build the largest possible installed base of printing devices that would go on to consume the high priced cartridges. In order to achieve this objective, the printing devices were priced at or below their true cost. By offering businesses and consumers low-cost printing devices then mass adoption was enabled. The cartridges subsidize the hardware so ultimately the consumers of the cartridges end up paying the true cost of the printer - it was just put off to some point in the future!

The OEMs are now caught between a rock and hard place. There's too much competition on the hardware side for them to successfully raise prices and charge consumers a fair market price for printers, so they have no choice but to rely on the profits from cartridges to subsidize the losses on the hardware. Because of this, there's unlikely to be any change to the OEM cartridge pricing model and the aftermarket competition is here to stay. Consumers can benefit from lower prices on high-quality aftermarket products.

The OEMs are now caught between a rock and hard place. There's too much competition on the hardware side for them to successfully raise prices and charge consumers a fair market price for printers, so they have no choice but to rely on the profits from cartridges to subsidize the losses on the hardware. Because of this, there's unlikely to be any change to the OEM cartridge pricing model and the aftermarket competition is here to stay. Consumers can benefit from lower prices on high-quality aftermarket products.

Competition works in

Competition works in

The high-quality aftermarket options that exist today are a far cry from those that existed 20-30 years ago and the OEMs are now forced to recognize both the threat and legitimacy of the aftermarket. By leveraging their market power with the few remaining Tier-1 resellers such as OfficeDepot, Staples, Walmart, etc., the OEMs have been able to restrict lower cost options from access to the largest markets and consumers have thereby been deprived of choice. However, the internet has leveled the playing field and the superstores are becoming increasingly irrelevant in terms of providing an outlet for office products.

The high-quality aftermarket options that exist today are a far cry from those that existed 20-30 years ago and the OEMs are now forced to recognize both the threat and legitimacy of the aftermarket. By leveraging their market power with the few remaining Tier-1 resellers such as OfficeDepot, Staples, Walmart, etc., the OEMs have been able to restrict lower cost options from access to the largest markets and consumers have thereby been deprived of choice. However, the internet has leveled the playing field and the superstores are becoming increasingly irrelevant in terms of providing an outlet for office products.

If you've ever wondered what alternatives there may be outside of what you can get from the superstores such as OfficeDepot and Staples, then why not install our app and, like magic, all your networked printers will be automatically "discovered", the ink and toner levels established, and then, over a 30-day period, the date those cartridges will run out will be calculated. All this information will be displayed on your dashboard. It's free and there's no obligation - just click on the link below to get started.